Design Update-3/1/07

Design Update-2/21/07

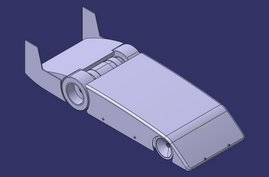

This is a project I have been working on for a couple months. I have been designing this on CATIA V5. It is electric and based on a RC10L3. My design uses a 3mm thick piece of carbon fiber for the main chassis and for the various rear suspension pieces. The motor is a Lehner 3060/7 which has a 1000 rpm/v rating. It uses 8s1p Li-Po for a total of 29.6 volts. This equates to a theoretical maximum rpm of 29,600 rpm with no load. The rear wheels are 79mm in diameter. At theoretical max rpm with no transmission or gear reduction (it is direct drive), the linear velocity is 273.87 mph. It will never reach that speed due to the high aerodynamic drag it will encounter. Wind tunnel testing needs to be done to calculate its drag coefficient. The car will also use a gyro for lateral stability. It will be used in a similar way as a gyro is used in helicopters and planes. If there is a gust of wind that forces the car to move in one direction, the gyro will sense this and compensate by sending a signal to the rudder servo. The rudder will move in a direction to counter the effect of the wind gust. It will help keep the model pointed in a straight line by dampening the effects of a cross wind. This is known as a heading hold mode on gyros.

This view shows the components with the body removed. The tail booms and vertical stabalizers have been left in place.

This view shows the components with the body removed. The tail booms and vertical stabalizers have been left in place.  More views of the X2 prototype

More views of the X2 prototype CATIA Model

CATIA ModelThis is still a work in progress as 90% of the design work is done. As you can see from my model, I don't have many of the smaller connecting hardware modelled. I also didn't fully model the parts that I knew would be using off the shelf. The idea of this initial model was to size up the components and to see if the design would be possible. All of the components needed to build this are modelled and fully detailed with dimensions. I have all the blueprints to build this (the drawing of the chassis is shown below as an example). After completing most of the modelling I can see that this will be possible except for one thing: cost.

Example of the chassis drawing with full dimensioning.

Example of the chassis drawing with full dimensioning.  Quick power required estimates (courtesy of Gordon Freeman)

Quick power required estimates (courtesy of Gordon Freeman)The problem is the cost of making some of these parts. The chassis parts aren't too expensive to produce. The expensive parts to be machined are the hubs used to attach the motor to the wheels. I also need the motor clamps to be machined. Initial pricing quotes for the CNC machining on the hubs is around $400... each! The motor costs around $700. All the suspension components can be taken from an RC10L3/4. I would like to make this car happen but I need help. If anyone could donate materials or skills in making this car, that would be awesome. If you know how to machine or can donate some pieces of 3mm carbon fiber, you'll be able to see your components be put together on this record setting car. Everyone who has helped make this happen can have a spot on the body of the vehicle for some much appreciated thanks and ad space (just like NASCAR)! If you would like to donate skills, email me at nick.maslowski@gmail.com. I can send you the specs and drawings for the components that you have the skills to make. Then I'll take your finished product and put it on the car. I will keep a detailed step by step construction process as I get the parts and post it here on this website. I wish I didn't have to beg from others, but I don't have the funds and would love to see something like this car built and run. I would like to have it complete in time for RC Car Action's Worlds Fastest RC Car contest on July 28, 2007.

Updated 2/16/07

Sponsors so far:

Batteries: Bob Burns at Thunder Power will supply the TP3300-4SX 14.8V 3300mAh 4-Cell packs, a charge and a balancer. These are the best Li-Pos around. Thanks Bob.

CNC machining: Aggressive Technologies has lent his CNC machining skills. Darren at Aggressive Technologies also mentioned that he knows pro driver Paul LeMieux. Paul Lemieux is one of the best touring car drivers in the world and has an impressive list of wins in the last few years. Hey Paul, do you want to drive this thing for me? Everyone knows that I can't drive. Plus, if you do wreck the car, I won't be responsible!

Carbon Fiber: I have been in contact with Matt at Ballistic Technology. He has done some excellent work on RC cars as well as top quality RC helicopters. He might have some extra carbon fiber to loan me. I have also contacted Wes at Out Front Frames. He has services available to make the chassis components.

Sponsors still needed:

Motor: Lehner can become a sponsor or someone can donate a Lehner 3060/7 motor for this car.

Speed Control: I have emailed Castle Creations asking if they would like to sponsor me. I am looking for a Castle Creations HV-110. If anyone has one available or would like to donate one, please contact me: nick.maslowski@gmail.com

5 comments:

200mph?

Your dreaming. Focus on beating the 134.4.

I heard there was another run which reached around 160. But crashed??? not sure.

150 is more realistic.

Well, they are having the contest again this year. So if they can reach 160mph last year, they are going to be trying to go faster than that. Plus 200 is a nice even number.

I think you really should ask for donations of cash also. People sometimes like to stay away from this, but it is probably your best bet for making this happen. There are plenty of people with a lot of cash, who can donate large sums of money. There are even more people, like me, who don't have a lot of money, but who could and would spare a smaller sum of money (like $5 to $10). Add these people up, and you'll hopefully have enough money to do this. Good luck to you, and I admire you for actually undertaking something like this.

were did you buy the motor i cant find it anywere?

The motor that I initially was going to use was a Lehner. But I did not get any support from them what so ever. I am using a Neu 2215/3Y:

http://www.neumotors.com/20061222/22%20series%20data.html

Post a Comment