Here is some video of when we first arrived at the drag strip. I start by slowly increasing my speeds on each pass. On the last pass you can hear buzzing as the car goes by. The buzzing sound is caused by the wheels becoming unbalanced as they lose more and more foam. In the pictures below you can see tire chunking. Top speed in this video was about 70 mph. Another thing to point out is how quiet the car is. Since this car has no gears or transmission, the only thing you really hear is the motor whine as the brakes are applied or if the chassis scrapes the ground. On faster runs all you can hear is the disturbed air as the car blows by. Around 3:10 is the fastest pass.

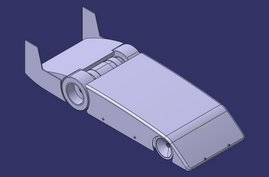

I made a new Lexan body to conform with the car driving backwards. On my previous test runs I found out that driving with the motor in front and drive wheels in front greatly improved stability. On the left is my old Futaba 1024 27 mhz PCM transmitter that yielded about 4x better range than my brand new Futaba 2.4 ghz 3PM.

I made a new Lexan body to conform with the car driving backwards. On my previous test runs I found out that driving with the motor in front and drive wheels in front greatly improved stability. On the left is my old Futaba 1024 27 mhz PCM transmitter that yielded about 4x better range than my brand new Futaba 2.4 ghz 3PM. One set of tires blown up.

One set of tires blown up. Another set of tires blown up.

Another set of tires blown up. Tire carnage from a day of high speed testing. I went through 4 sets of tires today. All had the same problem of self destructing. The adhesive between the rim and tire could not hold everything together.

Tire carnage from a day of high speed testing. I went through 4 sets of tires today. All had the same problem of self destructing. The adhesive between the rim and tire could not hold everything together. My max speed out of these tests was about 70-80mph. We were also using a radar gun to measure speed and it closely matched my on-board speed meter.

My max speed out of these tests was about 70-80mph. We were also using a radar gun to measure speed and it closely matched my on-board speed meter.I was able to get permission to test at the Houston Raceway. Its a full scale 1/4 mile drag strip on the east side of Houston in Baytown Texas. For this test I designed a new body out of Lexan. I was running 8s Li-Po 3300 mah Thunder Power batteries and a NEU 2215/3Y motor direct drive. I was not getting any range with my Futaba 2.4 ghz 3PM transmitter (only 100ft) so I went back and used my very old Futaba 27 mhz 1024 PCM transmitter. I was able to get almost 900ft of range with this old controller.

The results of my testing showed that around 70-80mph my TMRC drag racing tires would catastrophically fail. I would hear a very loud "crack" or "pop" as they would explode leaving foam all over the track. The car was not damaged in any way and was still very controllable even after tire failure.

After testing, I checked TMRC's website and it says that these tires have gone 107mph on nitro drag cars. I called and they said that other racers have encountered the same problem I have. They basically said that the tires might be hopping off the ground and free-wheeling for a split second. This causes the RPM's to go way up and the tires can fly apart. I will have to go back and try different spring and dampening combinations to minimize my wheel hop.

5 comments:

or increase the downforce on the front tires...

btw congrats on the marriage and good luck on race day

The problem with your tires tearing and why you cant go faster than 80 is because you need more traction in the front bt giving it more downforce in the front some how , i see that your design offers more down force in the front and nothing in the front because the front tires and motor are exposed

If you reduce the tire diameter to 3 or 4 millimeter sidewalls using tire lathe I'm pretty sure you could go to at least 120 mph before they explode. Good luck.

you could change the direct drive motor into a gear drive motor, cause of it's high Rpm (direct drive), it won't contribute to the speed anymore, instead it easily scrape off your tires even at low speeds.

machcat

you could change the direct drive motor into a gear drive motor, cause of it's high Rpm (direct drive), it won't contribute to the speed anymore, instead it easily scrapes off your tires even at low speeds.

machcat

Post a Comment