Caption for the video: For this test I designed a new body out of Lexan. For these tests I was running 8s Li-Po 3300 mah Thunder Power batteries and a NEU 2215/3Y ... all » motor direct drive. I was not getting any range with my Futaba 2.4 ghz 3PM transmitter (only 100ft) so I went back and used my very old Futaba 27 mhz 1024 PCM transmitter. I was able to get almost 900ft of range with my old controller.

The results of my testing showed that around 70-80mph my TMRC drag racing tires would catastrophically fail. They would explode leaving foam all over the track. The car was not damaged in any way.

Well, it looks like the word is spreading about my car and my attempt at 200mph with an rc car. This is great, except for all the wrong information that people have been posting. So far its been at:

Jalopnik

Digg

Autoblog

Engadget

OhGizmo

PistonHeads

Gizmodo

Almost all of the information is wrong in those posts so I will fix it here:

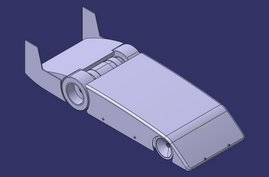

www.fastrc.blogspot.com is the website I started to follow the progress of all the high speed cars in the RC community. After months of reporting on other peoples cars, I decided to create my own high speed car. With my background in Aerospace Engineering I thought it would be a cool project.

The info in the post isn't correct, My name is Nick Maslowski and www.fastrc.blogspot.com is mine and the X2 is the car I designed and am testing now. Nic Case is the current record holder at 134.4 mph for an RC car. I just report on the high speed events and peoples cars, that is why he is on my website. His electrified nitro Associated TC3 went 134.4 mph at last years World Fastest RC car contest. This year he got 127.2 mph with an electrified Shumacher Fusion.

I use the website to post updates on my progress and post updates on other high speed contests. I started with the design phase on a CAD program called CATIA V5 (Boeing uses this program to design their planes, I work for Boeing as an aerospace engineer). I spent 6 months designing it, then 2 months ago I built it, and now I am testing the X2. My ultimate goal is to reach 200 mph by next years Worlds Fastest RC car contest held by RC Car Action magazine. What you see in that video is the first real ground test of the car. I had not gone above 30 mph before this video was shot. In that video I was able to get it up to around 80 mph. Then I had issues with the foam tires exploding due to the VHT on the surface and the coefficient of friction being very inconsistent. The car is still in the prototype stage. (you never see a new corvette being tested with a showroom floor finish, right? It always has a camo mask on and a lot of temporary aero pieces.) The whole car isn't finalized and is still subject to a lot of change before its final form. The guy taking the video is an older gentlemen and his health isn't the best. He is an expert in chassis design and suspension systems. He has helped me out a lot. The Houston raceway is the only place to open up a car like this. Its flat and I have plenty of room to wind it up and slow down.

I am working up to the cars full power from test to test. The average person doesn't know much about real RC cars and here is the info on this one: The finished power set-up will use a 12s (44v) Lithium Polymer battery from Thunder Power. The motor is a Neu brushless custom modified 2215/3y. It has a power capacity of 5000 watts (around 6.7 hp) and will be spinning the wheels at 21,000 rpms at 200 mph. The speed control is a Castle Creations HV-110 airplane controller. It can handle up to 44 volts and 110 amps continuous. No other RC car has this much power in such a small package.

If anyone else can build something faster, I'd love to see them try. Email me on my website at www.fastrc.blogspot.com about your try at these high speeds.

-Nick M.

2 comments:

Good work, sweet project, that Neu motor has a shaft coming out both ends, did Neu make that motor for you with the shafts like that or did you have it done somewhere else?

Neu made the shaft for me. I made drawings of what I wanted and they made the shaft to my specifications. It was pretty easy. I think the standard size is 8mm dia. And I asked for 1/4". So all they did was extend the shaft and grind it down to 1/4"

THanks for the comments

Post a Comment