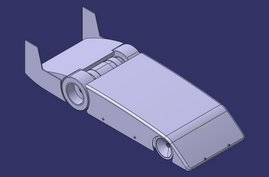

Well, if you guys have been following my progress you have seen that I have been having some bad luck with my car. I have been disappointed with myself that I haven't reached the speeds that I wanted. The heavy motor in the suspension system doesn't allow the shocks to compensate fast enough for the rough surface. I believe that is why my wheels would keep blowing. Too much sprung weight. I have been thinking of a new car to use. I have decided on an OFNA Ultra GTP. It is a 4wd shaft drive 1/8 scale gas buggy. I am going to convert it to fit the Neu 2215. This car is much heavier, but much beefier. It should be able to handle the 7hp (5000 Watt) Neu 2215. I already have the car and I started to layout the electronics. I am calling it "X3". I have designed the motor mount and it is being fabricated now.

"X3" This is the initial layout of the components. It is messy because its not permanent. I want to be able to move the electronics around until I find the best placement.

"X3"

"X2" on top, "X3" on the bottom

"X2" is on the back burner...for now.

"X2" in its last testing interation

I am not completely abandoning the "X2" design. I know it has a lot of potential but for now it requires too much tweaking to attain the speeds I would like in the time frame given. I am putting it on the back burner for now and I will return to it in the future.

"X3" This is the initial layout of the components. It is messy because its not permanent. I want to be able to move the electronics around until I find the best placement.

"X3" This is the initial layout of the components. It is messy because its not permanent. I want to be able to move the electronics around until I find the best placement.

4 comments:

correct me if i'm wrong, the reason of my comment before about the direct motor to wheel drive principle why it's not gonna work, is because of the too much revs it's causing(depending how powerful your motor is)that the rpm is way too much high, and since the motor shaft itself is the one serving as the wheel rotating in thousands of revolutions per minute, henceforth not creating anymore speed nor even torque at all, but instead just blowing up the tires easily irregardless of it's kind rubber or foam because of the too much tire pressure. excessively high rpm = lost of speed & torque/increase tire failure. Compared to your X3 now, it's a mark improvement than the X2 because of the 2 way gear set-up and it will gain more speed as well as torque with no more tire blown-ups. Just a suggestion though , I would rather use a 1/10 scale than 1/8 it would be lighter.

Hi

Brave move after all the devlopment of the X2 but the right one. I came to the conclusion that RC car designers have done all the hard work and we just need to adjust the gearing and power of an existing car to get the speed.

Keep the info coming

Thanks for the comments.

Anonymous - The final drive ratio on my X2 was 1:1 because the wheels were right on the motor shaft. No gear reduction. The RPM of the motor at 200 mph for a 3.25 inch tire is about 20,000. Now with my X3, I also have to have a final gear ratio of around 1:1 to reach the speeds I want. My initial testing will start with a final gear ratio of about 1.5:1. The OFNA has around a 3.1:1 internal gear ratio and I plan on running a 64 tooth pinion and a 32 pitch spur. This will get the final drive ration of around 1.5. The benefit of the OFNA is that I don't have that entire motor weight in the suspension. Hopefully I wont blow any tires. Nic Case and a number of drivers were blowing tires at the WFRCCC in '07. They believe it was caused by an inconsistent traction surface. One area would grip alot, the next would slip and cause wheel spin. And I think that is what cause blow outs.

Ziggy- I was hoping I could make my own design to beat some of the off the shelf cars, but you're right, they have done all the work already. Just put a ton of horsepower in it and tweak it until it goes fast, lol.

I'm going to update as much as I can! keep watching the site for updates.

Post a Comment