New wheel on the left, old wheel on the right. You can see there is much less sidewall of foam. Hopefully this will reduce the likelihood that the foam will fly off the rim. The new aluminum wheels are much heavier than the plastic ones, but they are much stronger.

New wheel on the left, old wheel on the right. You can see there is much less sidewall of foam. Hopefully this will reduce the likelihood that the foam will fly off the rim. The new aluminum wheels are much heavier than the plastic ones, but they are much stronger.

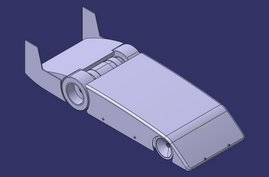

Pictures of the X2 progress in chronological order

Thursday, December 27, 2007

New wheels installed, "X2" ready for high speed testing

New wheel on the left, old wheel on the right. You can see there is much less sidewall of foam. Hopefully this will reduce the likelihood that the foam will fly off the rim. The new aluminum wheels are much heavier than the plastic ones, but they are much stronger.

New wheel on the left, old wheel on the right. You can see there is much less sidewall of foam. Hopefully this will reduce the likelihood that the foam will fly off the rim. The new aluminum wheels are much heavier than the plastic ones, but they are much stronger.Tuesday, December 11, 2007

More wheel designs

On the left is the 1/8 scale on road based wheel and on the right is a much larger OFNA style on road wheel. The OFNA based wheel has a much larger inside diameter and outside diameter. The idea with the OFNA based wheel is to minimize the sidewall size of the wheel while keeping the outside diameter close to 3.25". The tire needs to be trued down to correct size. You can also see that a hub isn't used to attach the wheel to the motor shaft. Instead a mount using setscrews is used to tighten the wheel on the motor shaft.

On the left is the 1/8 scale on road based wheel and on the right is a much larger OFNA style on road wheel. The OFNA based wheel has a much larger inside diameter and outside diameter. The idea with the OFNA based wheel is to minimize the sidewall size of the wheel while keeping the outside diameter close to 3.25". The tire needs to be trued down to correct size. You can also see that a hub isn't used to attach the wheel to the motor shaft. Instead a mount using setscrews is used to tighten the wheel on the motor shaft. Friday, November 16, 2007

Wing design

From my initial calculations, I need to get downforce on the front drive wheels in order to get enough traction to be able to accelerate at an acceptable rate. I am starting the wing design using a symmetric airfoil (NACA 0006). Ideally, I want to be able to create a significant amount of downforce at low speeds, then decrease downforce coefficient at higher speeds. I do not want to create too much downforce at high speeds. This will put unnecessary strain on the car and will increase drag significantly. The goal is to keep enough downforce on the drive wheels to create enough traction to get up to speed quickly. The idea is to have a flap that will start off at a large angle (60 degrees) then decrease angle as the speeds increase. This will lower the lift coefficient (downforce coefficient in my case), but maintain a certain downforce on the drive wheels throughout the speed range of the car.

This is a rough mock up of how the wing will be placed on the car. Because the wing is so close to the ground, ground effect will increase the wings effective downforce coefficient.

This is a rough mock up of how the wing will be placed on the car. Because the wing is so close to the ground, ground effect will increase the wings effective downforce coefficient.

Profile view of the NACA 0006 airfoil showing different degrees of flap.

Profile view of the NACA 0006 airfoil showing different degrees of flap.

Series of pictures illustrating how the flap will decrease in angle as speed increases:

This is a rough mock up of how the wing will be placed on the car. Because the wing is so close to the ground, ground effect will increase the wings effective downforce coefficient.

This is a rough mock up of how the wing will be placed on the car. Because the wing is so close to the ground, ground effect will increase the wings effective downforce coefficient. Profile view of the NACA 0006 airfoil showing different degrees of flap.

Profile view of the NACA 0006 airfoil showing different degrees of flap.Series of pictures illustrating how the flap will decrease in angle as speed increases:

Tuesday, November 13, 2007

More wheels and transmitter modifications

Wheels

Still working on more custom wheels. I want to try out a number of different wheels to see which ones will work best. I already have two types that I want to try. Each wheel has a different foam thickness.

Transmitter

I had just about given up on my 3PM transmitter until I found out that increasing the range on my Futaba 3PM 2.4 ghz transmitter isn't very difficult. There are a couple of off the shelf components that I found to increase range. Since 2.4 ghz is widely used in wireless internet, there are many places that sell components such as pig tails and amplifiers. I was able to open up my 3PM and see what kind of connectors were used for the antenna. Then I was able to find a 500mW amplifier to significantly increase my range. This is what the transmitter looks like with the modification:

Futaba 3PM 2.4 Ghz modified to increase range. Range of the stock transmitter is a measly 300ft. With this 500mW amp I have increased the range by about 3x.

Futaba 3PM 2.4 Ghz modified to increase range. Range of the stock transmitter is a measly 300ft. With this 500mW amp I have increased the range by about 3x.

Parts used:

Pig-Tail (U.FL to RP-SMA):

500mW Amplifier (RP-SMA):

Gyro:

Gyro:

I included a gryo into my setup. I found out that after I corrected the steering, the car had become much more sensitive with steering input. I tried all the adjustments to minimize this and nothing seemed to work. A number of people have said a gyro helps significantly. This gyro is nice because I can use the third channel on my transmitter to increase or decrease the sensitivity of the gyro without stopping the car to adjust the gyro itself. I can adjust it remotely.

Matt Shumaker described how a gyro affected his car. He has noted that at low speeds the gryo helps significantly by keeping the car on a straight trajectory with much less steering input from the driver. But at high speeds, the gyro makes the car feel numb. This is especially true if the gyro is too slow to compensate for movements in the steering.

Futaba GY401 next to the right rear wheel in the "X2"

Futaba GY401 next to the right rear wheel in the "X2"

Front end displaying the Thunder Power batteries and Castle Creations HV-110 performing perfectly during all of my testing.

Front end displaying the Thunder Power batteries and Castle Creations HV-110 performing perfectly during all of my testing.

I am still working on a wing to create downforce. The tight spaces on my car limit where I can mount a wing. I am now sizing the wing and airfoil section to create the desired amount of downforce at a certain speed.

Still working on more custom wheels. I want to try out a number of different wheels to see which ones will work best. I already have two types that I want to try. Each wheel has a different foam thickness.

Transmitter

I had just about given up on my 3PM transmitter until I found out that increasing the range on my Futaba 3PM 2.4 ghz transmitter isn't very difficult. There are a couple of off the shelf components that I found to increase range. Since 2.4 ghz is widely used in wireless internet, there are many places that sell components such as pig tails and amplifiers. I was able to open up my 3PM and see what kind of connectors were used for the antenna. Then I was able to find a 500mW amplifier to significantly increase my range. This is what the transmitter looks like with the modification:

Futaba 3PM 2.4 Ghz modified to increase range. Range of the stock transmitter is a measly 300ft. With this 500mW amp I have increased the range by about 3x.

Futaba 3PM 2.4 Ghz modified to increase range. Range of the stock transmitter is a measly 300ft. With this 500mW amp I have increased the range by about 3x.Parts used:

Pig-Tail (U.FL to RP-SMA):

500mW Amplifier (RP-SMA):

Gyro:

Gyro:I included a gryo into my setup. I found out that after I corrected the steering, the car had become much more sensitive with steering input. I tried all the adjustments to minimize this and nothing seemed to work. A number of people have said a gyro helps significantly. This gyro is nice because I can use the third channel on my transmitter to increase or decrease the sensitivity of the gyro without stopping the car to adjust the gyro itself. I can adjust it remotely.

Matt Shumaker described how a gyro affected his car. He has noted that at low speeds the gryo helps significantly by keeping the car on a straight trajectory with much less steering input from the driver. But at high speeds, the gyro makes the car feel numb. This is especially true if the gyro is too slow to compensate for movements in the steering.

Futaba GY401 next to the right rear wheel in the "X2"

Futaba GY401 next to the right rear wheel in the "X2" Front end displaying the Thunder Power batteries and Castle Creations HV-110 performing perfectly during all of my testing.

Front end displaying the Thunder Power batteries and Castle Creations HV-110 performing perfectly during all of my testing.I am still working on a wing to create downforce. The tight spaces on my car limit where I can mount a wing. I am now sizing the wing and airfoil section to create the desired amount of downforce at a certain speed.

Tuesday, October 16, 2007

New wheels and more street testing

Last time out testing at the Houston Dragway, I had problems with my tires holding together at speeds from 60-70mph. I have been working with my father to make some custom aluminum wheels using 1/8 scale on road tires. The wheels I have been using so far are 1/10 scale nitro drag tires:

These tires are very very soft and they are the correct outside diameter (3.25") and width (1.5") for the X2. Since these tires weren't working, I had to go a different route. The 1/8 scale tires are approximately the correct outside diameter (about 75-80mm) but they are much harder foam. The only problem is they are very wide (3"). What I did was to make my own aluminum rims and remove the foam from a 1/8 scale rim. This way I could use the same method of mounting (1/10th scale clamping hub). This is what I started with:

These tires are very very soft and they are the correct outside diameter (3.25") and width (1.5") for the X2. Since these tires weren't working, I had to go a different route. The 1/8 scale tires are approximately the correct outside diameter (about 75-80mm) but they are much harder foam. The only problem is they are very wide (3"). What I did was to make my own aluminum rims and remove the foam from a 1/8 scale rim. This way I could use the same method of mounting (1/10th scale clamping hub). This is what I started with:

I removed the foam from the 1/8 scale wheel and glued it onto the aluminum rim. Here's what the new wheel looks like (left) compared to the old one(right). The new wheel is much much stronger and should hold up to the extreme forces.

I removed the foam from the 1/8 scale wheel and glued it onto the aluminum rim. Here's what the new wheel looks like (left) compared to the old one(right). The new wheel is much much stronger and should hold up to the extreme forces.

I also modified the front suspension. I moved the tie rods from up above the upper arms to very low to maintain correct front end geometry:

I also modified the front suspension. I moved the tie rods from up above the upper arms to very low to maintain correct front end geometry:

Data from the last street run. Link to the FDR file from my run on 10-11-07. You can view this after downloading and installing the Eagle tree software.

Data from the last street run. Link to the FDR file from my run on 10-11-07. You can view this after downloading and installing the Eagle tree software.

I have also updated my spreadsheet. I added the ability to choose a motor based on what Kv and Kt requirements are calculated. I also added a section where you can calculate the amount of downforce created by a wing added to the car. And based on the traction created by this wing, you can see at what speed your total traction will intersect with your traction needed to accelerate at your desired rate.

Here is the link to download the spreadsheet for use on your own calculations.

Graph showing traction available vs traction needed. The point where the two lines intersect is the speed at which enough downforce will be created to give you the traction to accelerate without spinning the wheels.

Graph showing traction available vs traction needed. The point where the two lines intersect is the speed at which enough downforce will be created to give you the traction to accelerate without spinning the wheels.

I am still working on the wing and how to attach it to my car. Once the wing is completed and attached, I want to get out to the Houston Dragway as soon as I can to do some more high speed testing.

These tires are very very soft and they are the correct outside diameter (3.25") and width (1.5") for the X2. Since these tires weren't working, I had to go a different route. The 1/8 scale tires are approximately the correct outside diameter (about 75-80mm) but they are much harder foam. The only problem is they are very wide (3"). What I did was to make my own aluminum rims and remove the foam from a 1/8 scale rim. This way I could use the same method of mounting (1/10th scale clamping hub). This is what I started with:

These tires are very very soft and they are the correct outside diameter (3.25") and width (1.5") for the X2. Since these tires weren't working, I had to go a different route. The 1/8 scale tires are approximately the correct outside diameter (about 75-80mm) but they are much harder foam. The only problem is they are very wide (3"). What I did was to make my own aluminum rims and remove the foam from a 1/8 scale rim. This way I could use the same method of mounting (1/10th scale clamping hub). This is what I started with:

I removed the foam from the 1/8 scale wheel and glued it onto the aluminum rim. Here's what the new wheel looks like (left) compared to the old one(right). The new wheel is much much stronger and should hold up to the extreme forces.

I removed the foam from the 1/8 scale wheel and glued it onto the aluminum rim. Here's what the new wheel looks like (left) compared to the old one(right). The new wheel is much much stronger and should hold up to the extreme forces. I also modified the front suspension. I moved the tie rods from up above the upper arms to very low to maintain correct front end geometry:

I also modified the front suspension. I moved the tie rods from up above the upper arms to very low to maintain correct front end geometry: Data from the last street run. Link to the FDR file from my run on 10-11-07. You can view this after downloading and installing the Eagle tree software.

Data from the last street run. Link to the FDR file from my run on 10-11-07. You can view this after downloading and installing the Eagle tree software.I have also updated my spreadsheet. I added the ability to choose a motor based on what Kv and Kt requirements are calculated. I also added a section where you can calculate the amount of downforce created by a wing added to the car. And based on the traction created by this wing, you can see at what speed your total traction will intersect with your traction needed to accelerate at your desired rate.

Here is the link to download the spreadsheet for use on your own calculations.

Graph showing traction available vs traction needed. The point where the two lines intersect is the speed at which enough downforce will be created to give you the traction to accelerate without spinning the wheels.

Graph showing traction available vs traction needed. The point where the two lines intersect is the speed at which enough downforce will be created to give you the traction to accelerate without spinning the wheels.I am still working on the wing and how to attach it to my car. Once the wing is completed and attached, I want to get out to the Houston Dragway as soon as I can to do some more high speed testing.

Sunday, October 7, 2007

Road test with modifications for the "X2"

This is the modified steering. The orientation of the servo is unorthodox. I had trouble making sure that I had enough room for the antenna, receiver and switch after the steering had been rotated 180 degrees. Rather than place the servo laying flat on the chassis behind the steering suspension, I stood up the servo and placed it between the steering mounts to create more room for the electronics all the way in the rear of the car.

This is the modified steering. The orientation of the servo is unorthodox. I had trouble making sure that I had enough room for the antenna, receiver and switch after the steering had been rotated 180 degrees. Rather than place the servo laying flat on the chassis behind the steering suspension, I stood up the servo and placed it between the steering mounts to create more room for the electronics all the way in the rear of the car.  This is the front end of the car. This is where the pitot tube ports are located. A pitot tube is used on full size aircraft to measure airspeed. The dynamic pressure port is on the bottom. This port measure the forward airspeed as the car is running. The tube on top is for the static port. This measures the ambient pressure. The difference in the dynamic pressure and static pressure is speed. More info on pitot tubes can be found here.

This is the front end of the car. This is where the pitot tube ports are located. A pitot tube is used on full size aircraft to measure airspeed. The dynamic pressure port is on the bottom. This port measure the forward airspeed as the car is running. The tube on top is for the static port. This measures the ambient pressure. The difference in the dynamic pressure and static pressure is speed. More info on pitot tubes can be found here.

This is where the air travels down the brass tubes to the silicone tubes to the speed sensor. This is where the dynamic and static pressures are measured.

This is where the air travels down the brass tubes to the silicone tubes to the speed sensor. This is where the dynamic and static pressures are measured. This is data from a short test run I did on the street in front of my house. There is a lot of noise in the data from 0-8 seconds. The car wasn't even running on the ground between 1-8 seconds. After that, you can see from the spikes in the speed data that I made 4 passes. My fastest pass was about 18 mph.

This is data from a short test run I did on the street in front of my house. There is a lot of noise in the data from 0-8 seconds. The car wasn't even running on the ground between 1-8 seconds. After that, you can see from the spikes in the speed data that I made 4 passes. My fastest pass was about 18 mph. Currently I am working on getting new wheels put together and making a wing for some front end downforce. I will post more about these parts soon.

Monday, September 3, 2007

Update: Modifications

I have been working on changing a couple things for the X2. Since I am driving the car backwards, the front steering (now the back) needs to be turned around to keep the correct steering geometry. I turned the steering around 180 degrees. I also got some trailing front axles to keep excessive twitching of the steering to a minimum. I also changed the caster to -4 degrees.

I got an Eagle Tree Micrologger data acquisition system. This plugs in-between the Thunder Power batteries and Castle HV-110 speed control and can accurately measure a multitude of things. Currently it is measuring battery voltage, current, watts, mAh used, motor rpm and will include the airspeed sensor in the future.

I am also working on machining wheels out of aluminum. As you can see from my previous tests, I am having a hard time keeping the foam on the standard plastic rims. I want to experiment with some machined rims and different foam types to see if I can make a wheel that will hold up to the extreme performance of these speeds.

I am also working on a setup to provide downforce on the front wheels. My lack of acceleration is due to the fact that the coefficient of friction is lower than I expected. One way to increase traction without changing foam compound and increasing the weight of the car is to increase the downforce.

Here is a shot of the front suspension. It has been reversed to obtain the correct geometry. I installed trailing axle steering blocks to minimize the steering reaction. I also removed 1 set of washer from underneath the suspension arm mounts to increase the rear ride height to approximately 8mm. The upper arm mount shims were moved to provide -4 degrees of caster.

Here is a shot of the front suspension. It has been reversed to obtain the correct geometry. I installed trailing axle steering blocks to minimize the steering reaction. I also removed 1 set of washer from underneath the suspension arm mounts to increase the rear ride height to approximately 8mm. The upper arm mount shims were moved to provide -4 degrees of caster.

This is the Eagle Tree data acquisition micrologger. This will help me accuratley monitor voltage, speed, motor rpm and amp draw.

This is the Eagle Tree data acquisition micrologger. This will help me accuratley monitor voltage, speed, motor rpm and amp draw.

This is a sample graph of what the Micrologger can do. This example was from a quick bench test to see if everything was working. The car was freewheeling on the car stand. There seems to be some noise in the data. The only time the wheels were running is when you can see the rpm move into the 2 "humps" on the bottom of the graph. I was throttling up slowly to neutral then slowing down again. I did this twice. The data right before and after These rpm "humps" shouldnt be there since the motor wasnt even rotating. This could be caused by cogging of the brushless motor. You can see the rpm shoots up to 50,000 then goes to 0, which shouldn't happen.

This is a sample graph of what the Micrologger can do. This example was from a quick bench test to see if everything was working. The car was freewheeling on the car stand. There seems to be some noise in the data. The only time the wheels were running is when you can see the rpm move into the 2 "humps" on the bottom of the graph. I was throttling up slowly to neutral then slowing down again. I did this twice. The data right before and after These rpm "humps" shouldnt be there since the motor wasnt even rotating. This could be caused by cogging of the brushless motor. You can see the rpm shoots up to 50,000 then goes to 0, which shouldn't happen.

Wheels being machined

Wheels being machined

I got an Eagle Tree Micrologger data acquisition system. This plugs in-between the Thunder Power batteries and Castle HV-110 speed control and can accurately measure a multitude of things. Currently it is measuring battery voltage, current, watts, mAh used, motor rpm and will include the airspeed sensor in the future.

I am also working on machining wheels out of aluminum. As you can see from my previous tests, I am having a hard time keeping the foam on the standard plastic rims. I want to experiment with some machined rims and different foam types to see if I can make a wheel that will hold up to the extreme performance of these speeds.

I am also working on a setup to provide downforce on the front wheels. My lack of acceleration is due to the fact that the coefficient of friction is lower than I expected. One way to increase traction without changing foam compound and increasing the weight of the car is to increase the downforce.

Here is a shot of the front suspension. It has been reversed to obtain the correct geometry. I installed trailing axle steering blocks to minimize the steering reaction. I also removed 1 set of washer from underneath the suspension arm mounts to increase the rear ride height to approximately 8mm. The upper arm mount shims were moved to provide -4 degrees of caster.

Here is a shot of the front suspension. It has been reversed to obtain the correct geometry. I installed trailing axle steering blocks to minimize the steering reaction. I also removed 1 set of washer from underneath the suspension arm mounts to increase the rear ride height to approximately 8mm. The upper arm mount shims were moved to provide -4 degrees of caster.  This is the Eagle Tree data acquisition micrologger. This will help me accuratley monitor voltage, speed, motor rpm and amp draw.

This is the Eagle Tree data acquisition micrologger. This will help me accuratley monitor voltage, speed, motor rpm and amp draw.  This is a sample graph of what the Micrologger can do. This example was from a quick bench test to see if everything was working. The car was freewheeling on the car stand. There seems to be some noise in the data. The only time the wheels were running is when you can see the rpm move into the 2 "humps" on the bottom of the graph. I was throttling up slowly to neutral then slowing down again. I did this twice. The data right before and after These rpm "humps" shouldnt be there since the motor wasnt even rotating. This could be caused by cogging of the brushless motor. You can see the rpm shoots up to 50,000 then goes to 0, which shouldn't happen.

This is a sample graph of what the Micrologger can do. This example was from a quick bench test to see if everything was working. The car was freewheeling on the car stand. There seems to be some noise in the data. The only time the wheels were running is when you can see the rpm move into the 2 "humps" on the bottom of the graph. I was throttling up slowly to neutral then slowing down again. I did this twice. The data right before and after These rpm "humps" shouldnt be there since the motor wasnt even rotating. This could be caused by cogging of the brushless motor. You can see the rpm shoots up to 50,000 then goes to 0, which shouldn't happen. Wheels being machined

Wheels being machined

Saturday, August 18, 2007

New website

Updates on my car will continue to be at this website. The new website where I will keep all other fast RC cars will be at www.fastestrc.blogspot.com

I'm updating the site

I am going to make some big changes with my website. I started this website to keep a detailed record of all the fast RC car projects people are in progress. I also wanted to keep a detailed report of all the high speed events and have all that info in one place. But when I started on my project "X2" and detailing all of my progress, people were getting confused on who was making what car. For example, when Jalopnik reported on my car, they thought it was Nic Case who was making it:

So after reading this, I am going to change the website to show just my updates for my car. I will move all the other posts to a new website.

Most full sized vehicles can't hit 200 mph, let alone radio controlled cars (in actual miles per hour, not scale). But Nic Case hopes his X2, currently in development, will do just that. Current holder of RC car speed record of 134.4 mph, Nic's goal is nevertheless an optimistic one. Powered by a 29.6 Volt direct drive motor, the X2's theoretical top speed is 274 mph, but that's without any drag generated by friction with the road or air. Special foam tires capable of withstanding the incredibly high RPMs keep the diminutive car in contact with the track, while a gyroscope manipulates rudders to automatically keep it in a straight line. A video of the X2 running shakedown tests follows the jump.

So after reading this, I am going to change the website to show just my updates for my car. I will move all the other posts to a new website.

Friday, August 3, 2007

The word is getting out

Caption for the video: For this test I designed a new body out of Lexan. For these tests I was running 8s Li-Po 3300 mah Thunder Power batteries and a NEU 2215/3Y ... all » motor direct drive. I was not getting any range with my Futaba 2.4 ghz 3PM transmitter (only 100ft) so I went back and used my very old Futaba 27 mhz 1024 PCM transmitter. I was able to get almost 900ft of range with my old controller.

The results of my testing showed that around 70-80mph my TMRC drag racing tires would catastrophically fail. They would explode leaving foam all over the track. The car was not damaged in any way.

Well, it looks like the word is spreading about my car and my attempt at 200mph with an rc car. This is great, except for all the wrong information that people have been posting. So far its been at:

Jalopnik

Digg

Autoblog

Engadget

OhGizmo

PistonHeads

Gizmodo

Almost all of the information is wrong in those posts so I will fix it here:

www.fastrc.blogspot.com is the website I started to follow the progress of all the high speed cars in the RC community. After months of reporting on other peoples cars, I decided to create my own high speed car. With my background in Aerospace Engineering I thought it would be a cool project.

The info in the post isn't correct, My name is Nick Maslowski and www.fastrc.blogspot.com is mine and the X2 is the car I designed and am testing now. Nic Case is the current record holder at 134.4 mph for an RC car. I just report on the high speed events and peoples cars, that is why he is on my website. His electrified nitro Associated TC3 went 134.4 mph at last years World Fastest RC car contest. This year he got 127.2 mph with an electrified Shumacher Fusion.

I use the website to post updates on my progress and post updates on other high speed contests. I started with the design phase on a CAD program called CATIA V5 (Boeing uses this program to design their planes, I work for Boeing as an aerospace engineer). I spent 6 months designing it, then 2 months ago I built it, and now I am testing the X2. My ultimate goal is to reach 200 mph by next years Worlds Fastest RC car contest held by RC Car Action magazine. What you see in that video is the first real ground test of the car. I had not gone above 30 mph before this video was shot. In that video I was able to get it up to around 80 mph. Then I had issues with the foam tires exploding due to the VHT on the surface and the coefficient of friction being very inconsistent. The car is still in the prototype stage. (you never see a new corvette being tested with a showroom floor finish, right? It always has a camo mask on and a lot of temporary aero pieces.) The whole car isn't finalized and is still subject to a lot of change before its final form. The guy taking the video is an older gentlemen and his health isn't the best. He is an expert in chassis design and suspension systems. He has helped me out a lot. The Houston raceway is the only place to open up a car like this. Its flat and I have plenty of room to wind it up and slow down.

I am working up to the cars full power from test to test. The average person doesn't know much about real RC cars and here is the info on this one: The finished power set-up will use a 12s (44v) Lithium Polymer battery from Thunder Power. The motor is a Neu brushless custom modified 2215/3y. It has a power capacity of 5000 watts (around 6.7 hp) and will be spinning the wheels at 21,000 rpms at 200 mph. The speed control is a Castle Creations HV-110 airplane controller. It can handle up to 44 volts and 110 amps continuous. No other RC car has this much power in such a small package.

If anyone else can build something faster, I'd love to see them try. Email me on my website at www.fastrc.blogspot.com about your try at these high speeds.

-Nick M.

Tuesday, July 24, 2007

Video "X2" Update: Testing at Houston Raceway drag strip

Here is some video of when we first arrived at the drag strip. I start by slowly increasing my speeds on each pass. On the last pass you can hear buzzing as the car goes by. The buzzing sound is caused by the wheels becoming unbalanced as they lose more and more foam. In the pictures below you can see tire chunking. Top speed in this video was about 70 mph. Another thing to point out is how quiet the car is. Since this car has no gears or transmission, the only thing you really hear is the motor whine as the brakes are applied or if the chassis scrapes the ground. On faster runs all you can hear is the disturbed air as the car blows by. Around 3:10 is the fastest pass.

I made a new Lexan body to conform with the car driving backwards. On my previous test runs I found out that driving with the motor in front and drive wheels in front greatly improved stability. On the left is my old Futaba 1024 27 mhz PCM transmitter that yielded about 4x better range than my brand new Futaba 2.4 ghz 3PM.

I made a new Lexan body to conform with the car driving backwards. On my previous test runs I found out that driving with the motor in front and drive wheels in front greatly improved stability. On the left is my old Futaba 1024 27 mhz PCM transmitter that yielded about 4x better range than my brand new Futaba 2.4 ghz 3PM. One set of tires blown up.

One set of tires blown up. Another set of tires blown up.

Another set of tires blown up. Tire carnage from a day of high speed testing. I went through 4 sets of tires today. All had the same problem of self destructing. The adhesive between the rim and tire could not hold everything together.

Tire carnage from a day of high speed testing. I went through 4 sets of tires today. All had the same problem of self destructing. The adhesive between the rim and tire could not hold everything together. My max speed out of these tests was about 70-80mph. We were also using a radar gun to measure speed and it closely matched my on-board speed meter.

My max speed out of these tests was about 70-80mph. We were also using a radar gun to measure speed and it closely matched my on-board speed meter.I was able to get permission to test at the Houston Raceway. Its a full scale 1/4 mile drag strip on the east side of Houston in Baytown Texas. For this test I designed a new body out of Lexan. I was running 8s Li-Po 3300 mah Thunder Power batteries and a NEU 2215/3Y motor direct drive. I was not getting any range with my Futaba 2.4 ghz 3PM transmitter (only 100ft) so I went back and used my very old Futaba 27 mhz 1024 PCM transmitter. I was able to get almost 900ft of range with this old controller.

The results of my testing showed that around 70-80mph my TMRC drag racing tires would catastrophically fail. I would hear a very loud "crack" or "pop" as they would explode leaving foam all over the track. The car was not damaged in any way and was still very controllable even after tire failure.

After testing, I checked TMRC's website and it says that these tires have gone 107mph on nitro drag cars. I called and they said that other racers have encountered the same problem I have. They basically said that the tires might be hopping off the ground and free-wheeling for a split second. This causes the RPM's to go way up and the tires can fly apart. I will have to go back and try different spring and dampening combinations to minimize my wheel hop.

Sunday, July 15, 2007

Testing today - great success!

Today was a great testing day. I made awesome progress. Before today, I was having a ton a problems keeping the car pointed straight ahead. I could drive the car up to about 40 mph, then if I gave the car any kind of steering input, the car would fishtail and spin out. To fix the problem I tried changing camber/caster, spring weights, shock oil weights...anything. I was totally stuck then I got an idea. Run the car backwards. Run the car with the motor/drive wheels in the front and the steering in the back. I tried it and it worked great! Today I was able to get up to 60 mph (about 1/4 throttle) with no stability problems. I actually had too much straight line stability because I couldn't steer the car above 40mph. This issue has more to do with the sizing of the vertical stabilizers. I can use smaller ones for my next tests.

Acceleration was phenomenal and during braking the car would stay in a straight line without any effort. Today marks a huge milestone for my project "X2". I couldn't go any faster today because of the size of the area that we have to work with. Its only about 100 yards to work with. To get my car up to its full potential I need to find a much larger, flatter surface to test. Hopefully next weekend I'll be able to test at a much larger area.

The only problem for today is not being able to capture video of my car in action. We had technical difficulties with my camera and I wasn't able capture video with my car. But I did get a catch a close call with John's car. He was making a high speed pass and his car almost hit my full size car:

Subscribe to:

Comments (Atom)